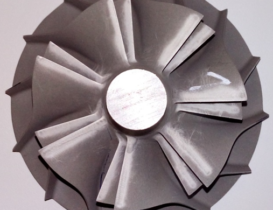

In the era of high demand for reduction of green gas pollution, safe and longtime (fatigue life) of a metal component operation in one aircraft or a nuclear power plant is of vital importance. Our goal is to develop treatment, which will by creation of a compressive residual stress as deep as possible into the material, increase fatigue life of those components. For this purpose, we are developing Laser Shock Peening (LSP) experimental station, while LSP among other surface treatments demonstrated deepest compressive residual stresses and consequently significantly increase fatigue life. Besides improvements of fatigue life, LSP can also be applied for prevention of stress corrosion, cracking/corrosion resistance, and wear resistance.

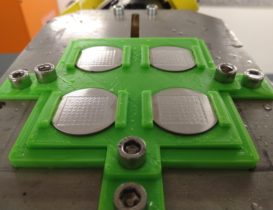

For LSP treatment under water as confining medium laser pulses (energy of 1 to 7 J, spot size from 2 mm x 2 mm to 5 mm x 5 mm) provided by BIVOJ laser system are applied to a sample mounted on the robot (Fanuc M-20iA/20M, load of up to 20 kg with 0.08 mm positioning repeatability). In order to ensure stable and reliable treatment the energy stability and laser beam profile are monitored by the diagnostic system based on two cameras (MANTA G-125, Allied Vision) and one calibrated photodiode.

The laboratory is equiped with state of the art devices for measurements of residual stress (Stresstech Hole drilling device and of Rigaku AutoMATE II system for measurement of residual stress based on X-ray technology) and metallography cell for sample preparation.

Team members: J. Kaufman (Team Leader), M. Bhöm, Sunil Pathak, Ondřej Stránský, Jan Šmaus.

LSP Business Development: S. Zulić

For more details about our LSP services please contact us at solutions@hilase.cz or read the LSP White Paper.