On 9th December 2025, the HiLASE Centre celebrated an important milestone in industrial laser innovation: the official opening of its new Laser Micromachining laboratory, developed as part of our long-term collaboration with Lockheed Martin.

The ceremony brought together partners and contributors who played key roles in turning this ambitious idea into a fully operational lab. The ceremonial ribbon was cut by:

- Tomáš Mocek, Head of the HiLASE Centre, who highlighted the strategic importance of the collaboration and its potential to strengthen the Czech Republic’s position in cutting-edge laser technologies.

- Milan Melichar, HiLASE Facility Team Leader, who oversaw the project’s implementation and ensured the smooth and timely construction of the laboratory, including the installation of specialised equipment.

- Todd Reinders, Program Manager for Czech Republic F-35 Industrial Participation at Lockheed Martin, representing project implementation and forward-looking partnership between our organisations.

- Pavel Dvořáček, Owner and Director of Narran s.r.o.

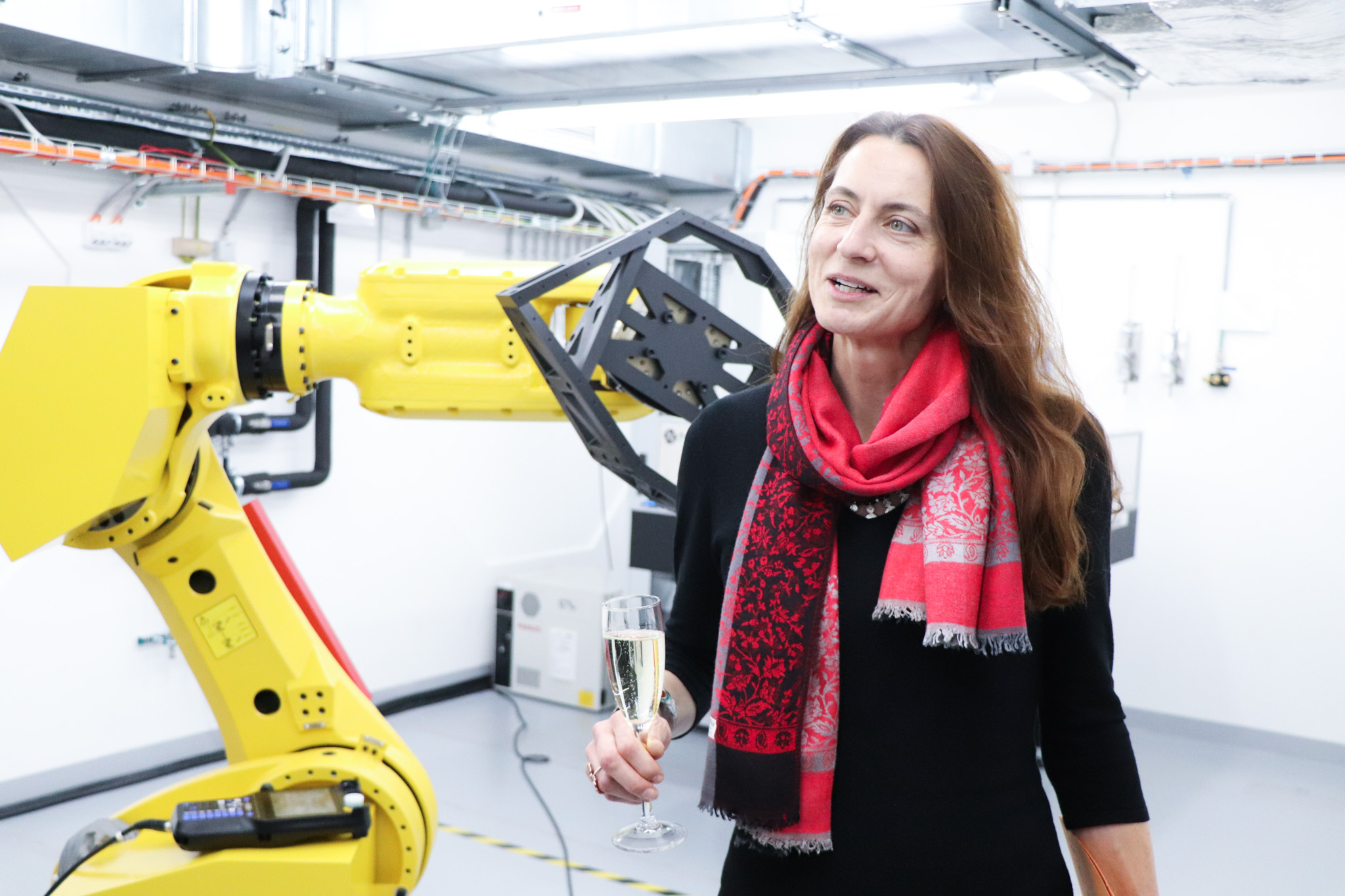

Following the ribbon cutting, the ceremony continued with the introduction of the new robotic workstation. To officially mark its launch, Radka Konderlová, Director General for Industrial Cooperation at the Ministry of Defence, performed a symbolic “christening” of the robot.

The new Laser Micromachining laboratory represents another step forward in our mission to translate world-class laser research into practical industrial solutions. It opens the door to high-precision machining applications for aerospace, defence, and advanced manufacturing, strengthening both Czech technological capabilities and international cooperation.

HiLASE Centre is proud to continue building bridges between research and industry. With partners like Lockheed Martin and Narran, we look forward to pushing the boundaries of what advanced laser technologies can achieve on a global scale.