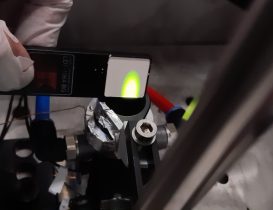

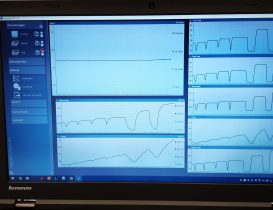

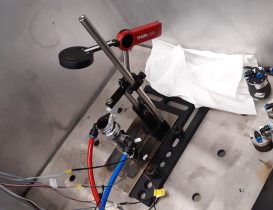

A new concept laser beam dump, developed within the LASER-PRO project through the collaboration of two Czech consortium members – the HiLASE Centre and CARDAM – is still undergoing intensive testing. The goal in this case is clear: to determine the beam dump’s behaviour under various operational conditions – especially different power loads. For these purposes, the beam dump was placed in a test setup where the scattering power of the laser beam, the output temperature of the cooling water, and the temperature of the beam dump itself at six different points were measured.

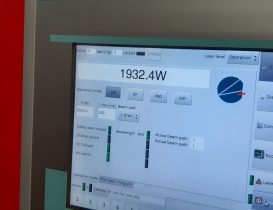

A Laserline LDF 9000-200 diode laser was used as the beam source, and a PM160T-HP power meter was used to measure scattering power. The laser beam power to which the beam dump was exposed was gradually increased from 200 up to 2,000 W.

Test parameters:

- Cooling water flow:5 litres/minute

- Water temperature at beam dump inlet: 2 °C

- Laser beam spot size: 10 mm

- Wavelength: 940 ± 10 nm

The beam dump showed no signs of excessive heating across the entire power range – the maximum measured body temperature of the beam dump under 2,000 W load was 54.5 °C, which can be considered a very satisfactory result given that this is the first design iteration. During testing, a visible mark was also identified at the point of laser beam impact. Although this is only a surface-level defect (thanks in part to the limited scope of testing), it is a highly valuable insight for further development, where it will be necessary to minimise this effect as much as possible.

The next testing phase currently underway is a long-term test of degradation of the internal structure caused by the flow of cooling water (i.e., resistance to corrosion and clogging). The results of these tests will serve as a valuable source of information for the design of the beam dump’s second iteration.

A Showcase of Excellence Hub Collaboration

This success story exemplifies the goals of the Horizon Europe-funded LASER-PRO project, which aims to advance European industrial competitiveness through regional collaboration and innovation in laser technologies. The beam dump initiative aligns with several LASER-PRO objectives:

- Advancing sustainable manufacturing processes

- Demonstrating successful academia-industry cooperation

- Promoting cross-border innovation transfer between research and SMEs

The project partners acknowledge the contributions of the entire testing team, including: Michal Chyla, Ye Jin Oh, Matěj Žáček and Marek Böhm.

About LASER-PRO

The LASER-PRO (Excellent Laser Technologies for the Sustainable Prosperity of Europe) project is a four-year initiative bringing together 18 partners from Czechia, Lithuania, and Ukraine. The project drives innovation in laser technologies across Europe by connecting research, industry, and policy actors – supporting sustainable manufacturing, accelerating digital transformation, and strengthening regional innovation ecosystems.

Learn more about LASER-PRO: www.laserpro-eh.eu/