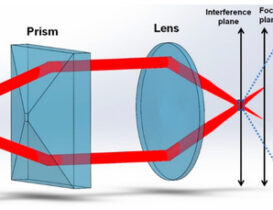

Young researcher Petr Hauschwitz in cooperation with other members of the HiLASE Centre team introduced a simple and effective method for increasing the throughput of surface functionalization in a new article „Large-Beam Picosecond Interference Patterning of Metallic Substrates” published for a Special Issue Advances in Laser Processing by MDPI.

If you you are eager to find out how to use this method of large-beam interference patterning in the combination with the HiLASE Centre Perla laser system, check the article here.

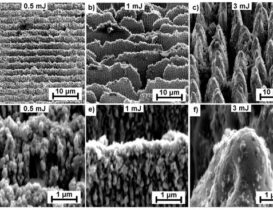

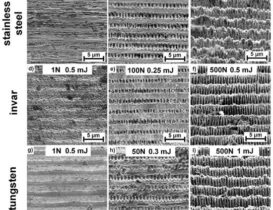

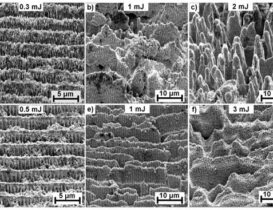

The newly developed method of large-beam interference patterning permits the production of micro and sub-micron sized features on a treated surface with increased processing throughputs by enlarging the interference area. The analyzed structures have shown superhydrophobic behavior with contact angles of 164°, 156°, and 150° in the case of stainless steel, invar, and tungsten, respectively.