High-quality microdrilling of transparent materials is very important for many industrial and scientific applications. The conventional mechanical methods encounter several drawbacks, including low precision and crack formation, and may require post ultrasonic or chemical processing. Hence, a single-step fast method is highly beneficial in this field. Three-dimensional microstructuring of bulk transparent materials using ultrashort laser pulses is a simple and widely used method, which finds applications in many fields such as fabrication of microfluidic devices, direct writing of optical waveguides, photopolymerization as well as three-dimensional drilling.

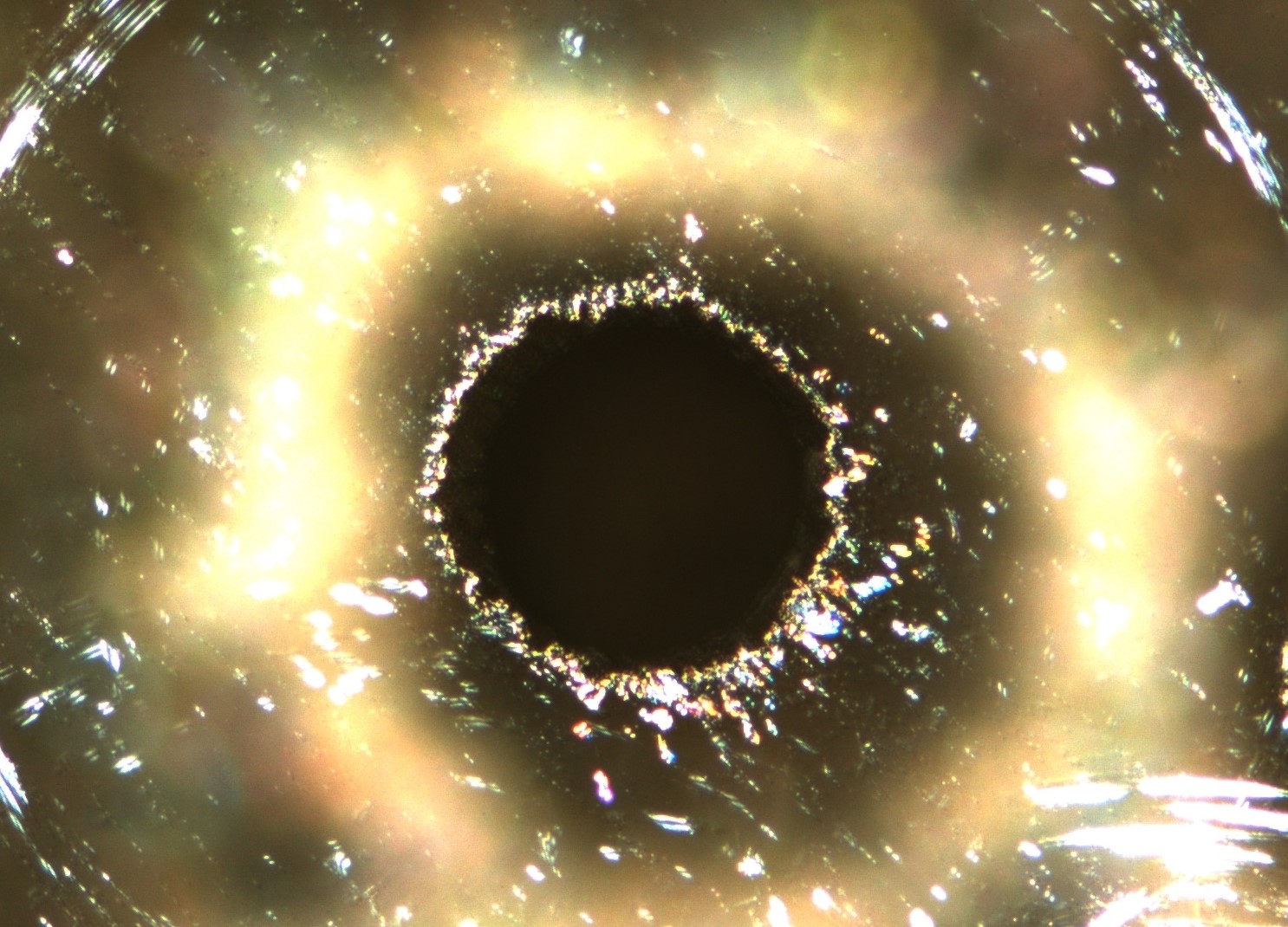

Dr. Martin Zukerstein and Dr. Inam Mirza from Scientific Laser Applications (SLA) Department in the HiLASE Centre have performed water-assisted laser drilling of 200-μm diameter through holes in ~1 mm thick fused silica substrates using infrared picosecond laser pulses. The fabricated holes show very low chipping and microcracks around their edges with the same entrance and exit diameters.

The microhole fabrication work was performed in collaboration with the FZU team of Materials for Nanosystems and Biointerfaces team led by Dr. Vincent Mortet from the Department of Functional Materials (Division of Condensed Matter Physics) for the fabrication of electrically conductive metallic vias in glass and their application in the development of electrochemical sensors within project SENZORVIR (TACR/MVCR/VI04000090).

More information about Scientific Laser Applications (SLA) Department can be found HERE.