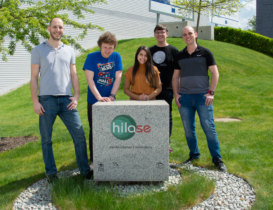

In early May, we were visited by scientists Renan Oss Giacomelli, Technical Leader/Researcher of Instituto SENAI de Inovação em Sistemas de Manufatura e Processamento a Laser, FIESC-SENAI, and his colleague, researcher Fernanda Correa. They are involved in the DOLASTOOL project on behalf of its Brazilian part.

“This visit was a crucial part of the technological transfer goal between Brazil and the Czech Republic: to work together in practical activities regarding the DOLASTOOL. The same will occur in Brazil in the week from 23.5 to 27.5, where our HiLASIAN friends will be able to work together with us. We also had the pleasure of getting to know the SHM team and their facilities in Šumperk”, says Renan Oss Giacomelli.

The DOLASTOOL project (Development and Optimisation of Laser-Based Additive, Subtractive and Transformative Platforms for the Tooling Industry) is the result of a bilateral call between Brazil and the Czech Republic with industry representatives Tupy, Welle Laser, and SHM joining forces with R&D institutions HiLASE Centre, Unidade EMBRAPII Manufatura a Laser (Instituto SENAI de Inovação em Processamento a Laser) and IT-CAS to develop and optimize a technological platform focused on advanced laser materials processing. Read more about the whole DOLASTOOL project HERE.

During their time spent at HiLASE, we asked Renan several questions about the project itself, their active cooperation with us, and their stay in the Czech Republic.

In what phase is the DOLASTOOL project at this moment?

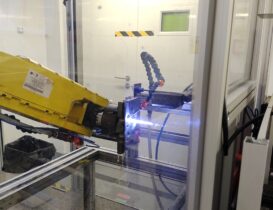

The DOLASTOOL is now in a more advanced phase, where the most promising technological cases have been structured and the selected technologies have been developed to the point of doing field tests with our partners industries.

What kind of experiment were you working on?

We were working with Laser Shock Peening experiments and characterization on parts from our Brazilian partner industry TUPY. Jan Kaufman, Team Leader of LSP, and his team led this task. The results were successful. We were able to demonstrate the levels of residual stress and the advantages and disadvantages of Laser Shock Peening in relation to conventional processes in our specific scenario.

How will the results impact the whole DOLASTOOL project?

The development of Laser Shock Peening in the SENAI Innovation Institute in Brazil will be greatly accelerated after this rich experience with the HiLASE team. All of this linked with important experimental work and results for the DOLASTOOL project.

Was it for the first time, that you and Fernanda were in the Czech Republic? Did you enjoy it? What do you like about the Czech Republic – Prague – Dolní Břežany?

Yes! We loved the cities and the experience of the daily life, food (Pivo too!) and the rich culture of Czech people. Prague and Dolní Břežany are so beautiful, we are looking forward to coming back!

How would you describe HiLASE Centre to other scientists and the research community?

HiLASE is a one-of-a-kind research facility, not only due to the impressive and unique laser facilities with the BIVOJ and PERLA lasers, but mostly due to the experienced and united team working on the applied research projects. We saw focused and results-driven people, always looking for ways to improve the state of the art and bring new technologies to the benefit of society. There are the obvious straightforward benefits of having access to technologies that are simply not yet available in Brazil, such as Laser Shock Peening, but there is more than that. By working together on a project we can create lasting and fruitful institutional and professional relationships which will open up new cooperation and development opportunities in the future.

Is there anything you want to say to HiLASIANS?

We would like to thank all of the HiLASE team members for welcoming us and making us feel like a part of the team for the time we were there, we loved working with you guys!! Special thanks to Jan Kaufman, Jan Brajer, and the LSP team that helped us organize the whole visit and put so much effort into making this work. We will do our best to treat you guys just as well in Brazil!