An article of our colleague Jan Kaufman has been recently published in the MDPI journal Metals. Jan has examined the effect of Laser Shock Peening parameters on residual stresses and corrosion fatigue of aluminium alloy 5083 (AA5083) and has come with interesting conclusions.

The aluminium alloy 5083 is a strong lightweight material known for its exceptional performance in extreme environments such as seawater, and exposure to industrial chemicals. Due to its excellent corrosion resistance, it is commonly used in the marine industry for the construction of hulls and other ship-related structures. However, when exposed to elevated temperatures ( over 50 °C) the alloy undergoes a process known as sensitization and becomes susceptible to intergranular corrosion.

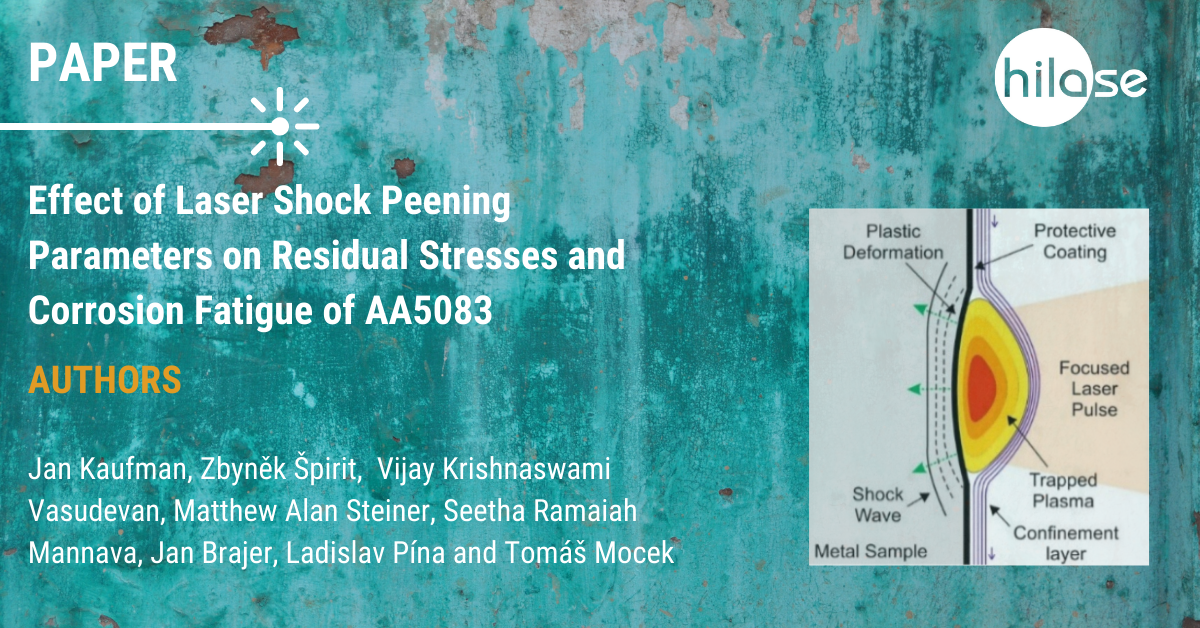

Jan has treated the alloy with Laser Shock Peening (both with and without protective coating – LPwC) in order to test its resistance to corrosion fatique.

The study has shown that LSP can reliably generate deep compressive residual stresses in the magnesium enhanced aluminium alloy, both with and without protective coating, which leads to significant improvement in corrosion fatigue.

If you want to learn more about our LSP services and how they can improve your manufacturing process, click HERE. To read the whole article, click HERE.