We are your partner in developing industrial relevant processes, which are not feasible with market existing laser sources. Our main objectives are to demonstrate the potential of a new generation of laser systems developed at HiLASE Centre in industrial applications and to initiate and influence further lasers development according to industrial demands.

Our focus now is to develop and optimize according to end users’ needs new and innovative processes in the fields of Efficient Laser Micromachining, Laser Shock Penning (LSP), and Laser Induced Damage Threshold (LIDT). For this purpose, we are developing experimental stations around HiLASE Centre laser systems using state of the art diagnostics, robotics, laser beam shaping and manipulation techniques. Among the most promising applications are micromachining applications (fabrication of functional large size surfaces, cutting, drilling, marking and many more) with efficiency and resulting quality above nowadays industrial standards, testing of damage threshold for optics and coatings in new laser radiation regimes, surface treatments to increase fatigue life of loaded parts by influencing residual stress, surface hardness, or corrosion resistance.

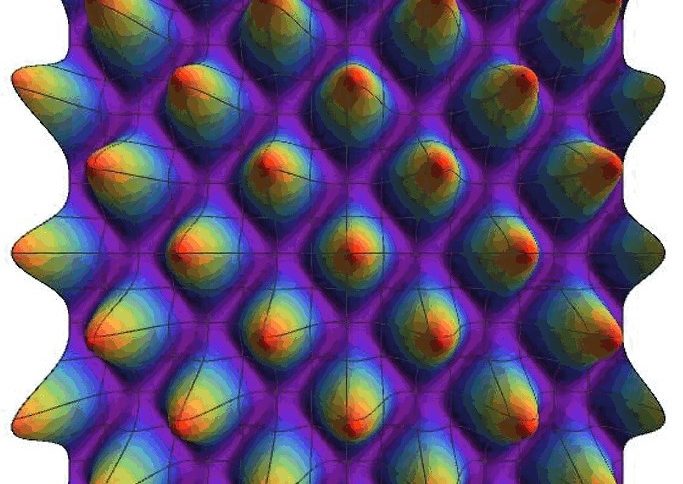

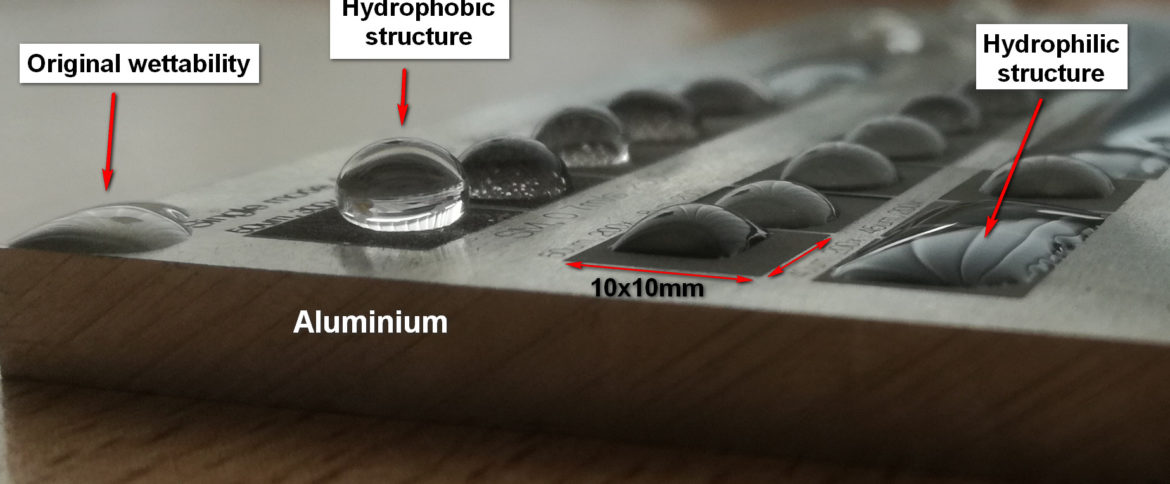

Efficient Laser Micromachining

Efficient fabrication of nano and microstructures in order to create functional surf...

Laser Induced Damage Threshold

Determination of Laser Induced Damage Threshold (LIDT) of newly designed optical com...

Laser Shock Peening

Laser treatment increasing fatigue life of laser components.